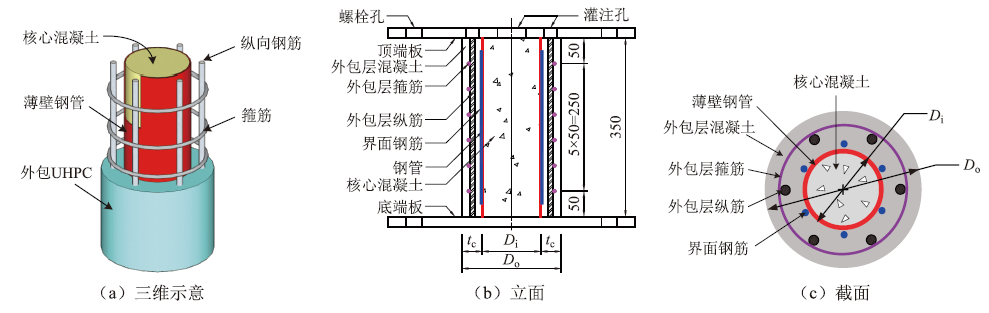

为进一步提高普通钢管混凝土叠合柱(简称“OC-CFST柱”)的受压承载力和耐久性,提出一种采用超高性能混凝土外包钢管混凝土叠合柱(简称“UC-CFST柱”),并开展22根(包括9根UC-CFST、9根OC-CFST和4根CFST)短柱试件的轴压试验,研究外包材料强度和面积占比对叠合短柱轴压性能和破坏模式的影响;同时,采用ABAQUS建立UC-CFST短柱的有限元模型,并开展了具有实际结构尺寸的短柱轴压性能有限元参数分析。研究结果表明:OC-CFST短柱破坏时外包层混凝土大面积剥落,而UC-CFST短柱由于UHPC中钢纤维的桥联作用,破坏时UHPC外包层比较完整。相比OC-CFST短柱,UC-CFST短柱的轴压刚度和轴压承载力均有显著提高,且在外包UHPC达到峰值压应变时达到轴压承载力。叠合柱外径不变时,随着外包混凝土面积占比的增加,UC-CFST短柱的轴压承载力近似线性增加,而OC-CFST短柱呈现线性递减趋势。最后,分析了采用现行钢管混凝土叠合柱结构技术规程中的轴压承载力公式计算UC-CFST短柱时的适用性,并在该规范公式的基础上建议不考虑0.9的附加系数,提出了可用于准确计算UC-CFST短柱轴压承载力的计算方法。

Abstract

To enhance the axial compressive bearing capacity and durability of concrete-encased concrete-filled steel tubular columns (referred to as OC-CFST columns), a novel approach utilizing ultra-high performance concrete (UHPC) encased CFST (UC-CFST columns for short) was proposed. A total of 22 stub column specimens were tested under axial compression, including nine UC-CFST columns, nine OC-CFST columns, and four CFST columns.The investigation aimed to assess the impact of encasing material strength and area ratio on the axial compressive performance and failure mode. Finite element models of the UC-CFST stub column were established using ABAQUS, and a parameter analysis of axial compression performance was conducted on the stub columns with real structural dimensions. The results reveal that during failure of OC-CFST stub columns, the encasing ordinary concrete suffers extensive peeling, while UC-CFST stub columns experience relatively intact due to the bridging effect of steel fibers within the UHPC. Compared to the OC-CFST stub columns, the UC-CFST stub columns exhibit significantly improving axial compressive stiffness and axial compressive bearing capacity, and reach axial compressive bearing capacity when the UHPC encasing reaches its peak compressive strain. Furthermore, while maintaining the outer diameter of composite columns constant, the axial compressive bearing capacity of UC-CFST stub columns demonstrate an approximately linear increase with the rise in area ratio of encasing concrete, while the OC-CFST stub columns exhibit a linear decreasing trend. Finally, the applicability of using the formula in the current technical specifications for steel tube-reinforced concrete column structures to calculate the axial compressive bearing capacity of UC-CFST stub columns was analyzed. Based on this formula, it was recommended not to consider the additional coefficient of 0.9 and a new calculation method was proposed to accurately determine the axial compressive bearing capacity of UC-CFST stub columns.

关键词

钢管混凝土叠合柱 /

外包超高性能混凝土 /

轴压试验 /

有限元分析 /

破坏形态 /

轴压承载力

{{custom_keyword}} /

Key words

concrete-encased CFST composite column /

UHPC-encased /

axial compression test /

finite element analysis /

failure pattern /

axial compressive bearing capacity

{{custom_keyword}} /

{{custom_sec.title}}

{{custom_sec.title}}

{{custom_sec.content}}

参考文献

[1] LI Shuai, HAN Linhai, HOU Chao. Concrete-encased CFST columns under combined compression and torsion: analytical behavior [J]. Journal of Constructional Steel Research, 2018, 144: 236-252.

[2] 康洪震,钱稼茹.钢管高强混凝土组合柱轴压承载力试验研究[J].建筑结构,2011,41(6):64-67. (KANG Hongzhen, QIAN Jiaru. Experimental study on axial compressive capacity of high strength concrete-filled steel tube composite columns[J]. Building Structure, 2011, 41(6):64-67. (in Chinese))

[3] 郭全全,赵羽西,李芊,等.钢管混凝土叠合柱偏心受压性能试验研究[J].建筑结构学报,2013,34(12):103-111. (GUO Quanquan, ZHAO Yuxi, LI Qian, et al. Experimental study on eccentric compressive property of steel tube-reinforced concrete columns [J]. Journal of Building Structures, 2013, 34(12): 103-111. (in Chinese))

[4] LEE Hojun, PARK Honggun, CHOI Inrak. Eccentric compression behavior of concrete-encased-and-filled steel tube columns with high-strength circular steel tube [J]. Thin-Walled Structures, 2019, 144: 106339.

[5] 钱稼茹,康洪震.钢管高强混凝土组合柱抗震性能试验研究[J].建筑结构学报,2009,30(4):85-93. (QIAN Jiaru, KANG Hongzhen. Experimental study on seismic behavior of high-strength concrete-filled steel tube composite columns [J]. Journal of Building Structures, 2009, 30(4): 85-93. (in Chinese))

[6] JI Xiaodong, KANG Hongzheng, CHEN Xingchen, et al. Seismic behavior and strength capacity of steel tube-reinforced concrete composite columns [J]. Earthquake Engineering & Structural Dynamics, 2014, 43(4): 487-505.

[7] CAI Jingming, PAN Jinlong, LI Xiaopeng. Behavior of ECC-encased CFST columns under axial compression [J]. Engineering Structures, 2018, 171: 1-9.

[8] 陈宝春,季韬,黄卿维,等.超高性能混凝土研究综述[J].建筑科学与工程学报,2014,31(3):1-24. (CHEN Baochun, JI Tao, HUANG Qingwei, et al. Review of research on ultra-high performance concrete[J]. Journal of Architecture and Civil Engineering, 2014, 31(3):1-24. (in Chinese))

[9] RUSSELL Henryg, GRAYBEAL Benjamina. Ultra-high performance concrete: a state-of-the-art report for the bridge community[R]. Washington DC: Federal Highway Administration, 2013.

[10]SCHMIDT Michael, FEHLING Ekkehard. Ultra-high-performance concrete: research, development and application in Europe [J]. ACI Special Publication, 2005, 228: 51-78.

[11]邵旭东,樊伟,黄政宇.超高性能混凝土在结构中的应用[J].土木工程学报,2021,54(1):1-13. (SHAO Xudong, FAN Wei, HUANG Zhengyu. Application of ultra-high-performance concrete in engineering structures [J]. China Civil Engineering Journal, 2021, 54(1): 1-13.(in Chinese))

[12]PARK Seunghun, KIM Dongjoo, RYU Gumsung, et al. Tensile behavior of ultra-high performance hybrid fiber reinforced concrete [J]. Cement & Concrete Composites, 2012,34:172-184.

[13]邵旭东,邱明红,晏班夫,等.超高性能混凝土在国内外桥梁工程中的研究与应用进展[J].材料导报, 2017,31(23):33-43. (SHAO Xudong, QIU Minghong, YAN Banfu, et al. A review on the research and application of ultra-high performance concrete in bridge engineering around the world[J]. Materials Review, 2017, 31(23):33-43. (in Chinese))

[14]陈宝春,韦建刚,苏家战,等.超高性能混凝土应用进展[J]. 建筑科学与工程学报, 2019, 36(2):10-20. (CHEN Baochun, WEI Jiangang, SU Jiazhan, et al. State-of-the-art progress on application of ultra-high performance concrete[J]. Journal of Architecture and Civil Engineering, 2019,36(2):10-20. (in Chinese))

[15]钢管混凝土叠合柱结构技术规程: T/CECS 188:2019[S]. 北京: 中国建筑工业出版社, 2020. (Technical specification for steel tube-reinforced concrete column structures: T/CECS 188:2019[S]. Beijing: China Architecture & Building Press, 2020. (in Chinese))

[16]钢管混凝土结构技术规范: GB 50936—2014[S]. 北京: 中国建筑工业出版社, 2014. (Technical code for concrete filled steel tubular structures: GB 50936—2014 [S]. Beijing: China Architecture & Building Press, 2014. (in Chinese))

[17]混凝土物理力学性能试验方法标准: GB/T 50081—2019[S]. 北京:中国建筑工业出版社, 2019. (Standard for test methods of concrete physical and mechanical properties: GB/T 50081—2019 [S]. Beijing: China Architecture & Building Press, 2019. (in Chinese))

[18]超高性能混凝土基本性能与试验方法: T/CBMF 37—2018[S]. 北京: 中国建材工业出版社, 2018. (Fundamental characteristics and test methods of ultra-high performance concrete: T/CBMF 37—2018 [S]. Beijing: China Building Materials Press, 2018. (in Chinese))

[19]金属材料 拉伸试验:第1部分: 室温试验方法: GB/T 228.1—2021[S]. 北京:中国标准出版社,2021. (Metallic materials:tensile testing:part 1: method of test at room temperature: GB/T 228.1—2021 [S]. Beijing: Standards Press of China, 2021. (in Chinese))

[20]陈宗平,黄乐彰,谭秋虹.方钢管螺旋筋混凝土柱偏压性能试验及参数分析[J].工程力学,2021,38(1):205-219. (CHEN Zongping, HUANG Lezhang, TAN Qiuhong. Experimental study and analysis of concrete filled square steel tube columns with spiral reinforcement under eccentric compression [J]. Engineering Mechanics, 2021, 38(1):205-219. (in Chinese))

[21]HAN Linhai, YAO Guohuang, TAO Zhong. Performance of concrete-filled thin-walled steel tubes under pure torsion [J]. Thin-Walled Structures, 2007, 45 (1): 24-36.

[22]混凝土结构设计规范: GB 50010—2010[S]. 2015版. 北京: 中国建筑工业出版社, 2015.(Code for design of concrete structures: GB 50010—2010 [S]. 2015 ed. Beijing: China Architecture & Building Press, 2015. (in Chinese))

[23]韩林海. 钢管混凝土结构:理论与实践 [M]. 3版. 北京:科学出版社, 2007.(HAN Linhai. Concrete-filled steel tubular structures: theory and practice [M]. 3rd ed. Beijing: China Science Press, 2007. (in Chinese))

{{custom_fnGroup.title_cn}}

脚注

{{custom_fn.content}}

基金

国家自然科学基金项目(51978169),福建省科技计划项目(2021H6021),福建省交通运输科技发展计划(202211)。

{{custom_fund}}

PDF(3956 KB)

PDF(3956 KB)

PDF(3956 KB)

PDF(3956 KB)

PDF(3956 KB)

PDF(3956 KB)