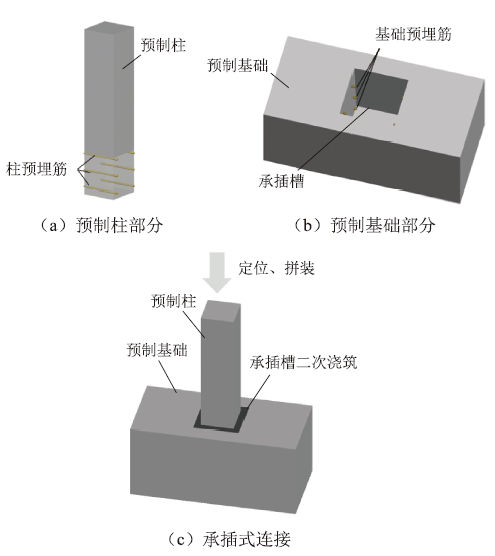

为增强预制混凝土柱与基础间承插结合面的黏结性能,提出一种在连接区域设置预埋筋的预制混凝土柱-基础承插式连接构件。设计并制作6个承插式连接构件和1个现浇构件进行拟静力试验,通过对其滞回曲线、骨架曲线和钢筋应变等进行分析,研究轴压比、预埋筋布置形式等参数对承插式连接构件抗震性能的影响,并利用 ABAQUS软件进行有限元分析,探究所设预埋筋的工作机制及有效埋深范围。结果表明:承插式连接构件的抗震性能与现浇构件基本相当,所有构件的破坏模式均为柱底压弯破坏,且极限位移角均满足现行规范位移角限值1/60的要求;在轴压比0~0.264范围内,随轴压比增大,承插式连接构件的承载力提高,但延性有所降低;适当增大轴压比可以提高承插式连接构件后期的耗能能力;预埋筋的设置可使承插式连接构件的埋深适当降低,采用两排倒三角布置形式的承插式连接构件具有更好的延性,加载后期承载力退化水平更低。

Abstract

A precast concrete column-to-foundation socket connection with embedded reinforcement in the joint area was proposed in this paper to enhance the bonding of the socket joint between the precast concrete column and foundation. Six socket connection specimens and one reference cast-in-place specimen were designed and manufactured for pseudo-static tests. The hysteretic curves, skeleton curves, and the strains of steel bars of the specimens were analyzed, aiming to investigate the effect of the axial compression ratio and the layout of embedded reinforcement on the seismic performance of the socket connections. Finite element analysis was conducted using ABAQUS to explore the mechanism and the effective depth of the embedded reinforcement. The results show that the seismic performance of socket connection specimens is equivalent to that of the cast-in-place specimen and the failure mode of all components is compression bending damage at the bottom of the column, with their ultimate drift angles exceeding 1/60 and meeting the requirement of the current code limits. The increase of the axial compression ratio from 0 to 0.264 leads to an increase in the ultimate bearing capacity of the specimens but a reduction in the ductility. Meanwhile, the energy dissipation capacity of the specimens may be improved in the later stage. The embedded reinforcement can reduce the buried depth of the socket connection specimens. The socket connection specimens with two rows of inverted triangular embedded reinforcement exhibit better ductility with a lower level of post-peak strength degradation.

关键词

预制混凝土柱 /

承插式连接 /

预埋筋 /

拟静力试验 /

抗震性能

{{custom_keyword}} /

Key words

precast concrete column /

socket connection /

embedded reinforcement /

pseudo-static test /

seismic behavior

{{custom_keyword}} /

{{custom_sec.title}}

{{custom_sec.title}}

{{custom_sec.content}}

参考文献

[1] 装配式混凝土框架节点与连接设计标准: T/CECS 43—2021 [S]. 北京:中国计划出版社, 2021.(Design standard for joints and connections of precast frames: T/CECS 43—2021 [S]. Beijing: China Planning Press, 2021. (in Chinese))

[2] 丁世聪, 韩艳,王江江,等. 承插式预制桥墩抗震性能研究综述[J]. 安徽建筑, 2020, 27(10): 59-61.(DING Shicong, HAN Yan, WANG Jiangjiang, et al. Summary of research on seismic performance of socket-type precast piers [J]. Anhui Architecture, 2020, 27(10): 59-61. (in Chinese))

[3] RIVA P, BELLERI A. Seismic behaviour of precast column-to-foundation grouted sleeve connections[C] //Proceedings of an International Conference on Advances in Engineering Structures, Mechanics & Construction. Dordrecht: Springer,2006:121-128.

[4] MOHEBBI A, SAIIDI M S, ITANI A M. Shake table studies and analysis of a precast two-column bent with advanced materials and pocket connections[J]. Journal of Bridge Engineering, 2018, 23(7): 1-14.

[5] ANIL O, UYAROGLU B. Nonlinear finite element analysis of loading transferred from column to socket base[J]. Computers and Concrete, 2013, 11(5): 475-492.

[6] 徐艳,曾增,葛继平,等.承插式预制拼装墩柱的最小合理承插深度[J].同济大学学报(自然科学版),2019,47(12):1706-1711.(XU Yan, ZENG Zeng, GE Jiping, et al. Minimum reasonable socket depth of precast pier-footing with socket connection[J]. Journal of Tongji University (Natural Science), 2019, 47(12): 1706-1711. (in Chinese))

[7] HARALDSSON O S, JANES T M, EBERHARD M O, et al. Seismic resistance of socket connection between footing and precast column[J]. Journal of Bridge Engineering, 2013, 18(9): 910-919.

[8] TRAN H, STANTON J, EBERHARD M. Precast bent system for high seismic regions: laboratory tests of column-to-drilled shaft socket connections [J]. Bridge Construction, 2013, 15(8): 158-168.

[9] PUL S, HUSEM M, ARSLAN M E, et al. An experimental study on different socket base connections under cyclic loading[J]. Computers and Concrete, 2014, 13(3): 377-387.

[10]陈金彪. 装配式桥梁预制空心桥墩与承台连接性能的研究与应用[D]. 合肥: 合肥工业大学, 2017:61-63. (CHEN Jinbiao. Study and application on connection performance of prefabricated bridge precast hollow bridge pier and pile cap[D]. Hefei: Hefei University of Technology, 2017:61-63. (in Chinese))

[11]冷大伟. 预制管型墩柱与承台杯口式连接性能试验[J]. 公路交通科技(应用技术版),2018, 14(9): 266-268. (LENG Dawei. Performance test of cup connection between precast tubular pier and pile cap[J]. Journal of Highway and Transportation Research and Development(Application Technology Version), 2018,14(9):266-268. (in Chinese))

[12]OSANAI Y, WATANABE F, OKAMOTO S. Stress transfer mechanism of socket base connections with precast concrete columns[J]. ACI Structural Journal, 1996, 93(3): 266-276.

[13]建筑抗震设计规范:GB 50011—2010[S]. 2016版. 北京:中国建筑工业出版社, 2016. (Code for seismic design of buildings: GB 50011—2010[S]. 2016 ed. Beijing:China Architecture & Building Press, 2016. (in Chinese))

[14]PARK R. Evaluation of ductility of structures and structural assemblages from laboratory testing[J]. Bulletin of the New Zealand Society for Earthquake Engineering, 1989, 22(3): 155-166.

[15]建筑抗震试验规程:JGJ 101—2015[S]. 北京:中国建筑工业出版社,2015. (Specification for seismic test of buildings: JGJ 101—2015 [S]. Beijing: China Architecture & Building Press,2015. (in Chinese))

[16]路林海, 韩帅, 陈振兴, 等. 采用承插式桩接头的预制方桩受弯承载性能研究[J]. 建筑结构学报, 2018, 39(2): 153-161. (LU Linhai, HAN Shuai, CHEN Zhenxing, et al. Study on bending performance of prefabricated square pile with socket and spigot joint[J]. Journal of Building Structures, 2018, 39(2): 153-161. (in Chinese))

[17]黄璐, 卓卫东, 上官萍, 等. 新旧混凝土黏结面剪切强度的改进计算式[J]. 工业建筑, 2018, 48(8): 202-207. (HUANG Lu, ZHUO Weidong, SHANGGUAN Ping, et al. An improved formula for shear strength of bonding interface between new and old concrete[J]. Industrial Construction, 2018, 48(8): 202-207. (in Chinese))

[18]殷芝霖, 李玉温. 钢筋混凝土结构中预埋件的设计方法(一): 受剪预埋件[J]. 工业建筑, 1988, 18(4): 42-51. (YIN Zhilin, LI Yuwen. Design method of embedded parts in reinforced concrete structures:I:shear embedded parts[J]. Industrial Construction, 1988, 18(4): 42-51. (in Chinese))

{{custom_fnGroup.title_cn}}

脚注

{{custom_fn.content}}

基金

国家自然科学基金项目(52178139)。

{{custom_fund}}

PDF(8586 KB)

PDF(8586 KB)

PDF(8586 KB)

PDF(8586 KB)

PDF(8586 KB)

PDF(8586 KB)